- Home Page

- Company Profile

-

Our Products

- Roots Blower

- Cement Feeding System

- Blower Machine

- Twin Lobe Roots Blower

- Water Ring Vacuum Pump

- Twin Lobe Compressor

- Air Blower Accessories

- Twin Lobe Air Blowers

- Bulker Unloading System

- Cement Silo

- Industrial Gear Pair

- Industrial Air Compressor

- Air Cooled Blowers

- Rotor Pair

- Bulkar Unloading System Blower

- Vacuum Boosters

- Gallery

- Contact Us

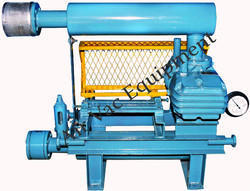

Twin Lobe Roots Blower for Effluent Treatment

95000 INR/Unit

Product Details:

- Equipment Type Roots Blower

- Material Cast Iron / Mild Steel / Stainless Steel

- Processing Type Standard

- Condition New

- Technology Twin Lobe Roots (Positive Displacement)

- Dimension (L*W*H) Varies by Model (Compact Design)

- Power Mode Electric

- Click to view more

X

Twin Lobe Roots Blower for Effluent Treatment Price And Quantity

- 95000 INR/Unit

- 1

- Floor Mounted

- Clockwise (CW) / Counter-Clockwise (CCW) as required

- Long Operational Life with Low Maintenance

- Ambient to 45°C

- Below 85 dB(A)

- Air Cooled

- Two Lobe

- 25 m³/hr to 10,000 m³/hr

- 1" to 14"

- Smooth Finished Housing

- V-Belt/Direct Coupled

- Oil Splash Lubrication

Twin Lobe Roots Blower for Effluent Treatment Product Specifications

- 220V/380V/415V, 3 Phase, 50 Hz

- Base Frame, Inlet & Outlet Silencer, Safety Valve, V-Belt Drive, Motor Pulley, Suction Filter, NRV

- Electric

- 0.1 to 1 Bar (1000 to 10000 mmWG)

- Twin Lobe Roots (Positive Displacement)

- Cast Iron / Mild Steel / Stainless Steel

- Varies by Model (Compact Design)

- Roots Blower

- New

- Anti-Corrosion Paint Coating

- 0.5 HP to 100 HP

- Effluent Treatment Plant (ETP), Sewage Treatment Plant (STP), Wastewater Aeration

- Standard

- Floor Mounted

- Clockwise (CW) / Counter-Clockwise (CCW) as required

- Long Operational Life with Low Maintenance

- Ambient to 45°C

- Below 85 dB(A)

- Air Cooled

- Two Lobe

- 25 m³/hr to 10,000 m³/hr

- 1" to 14"

- Smooth Finished Housing

- V-Belt/Direct Coupled

- Oil Splash Lubrication

Twin Lobe Roots Blower for Effluent Treatment Trade Information

- 20 Per Month

- 30 Days

- Wooden Box Packaging

- All India

Product Description

In effluent treatment, Twin Lobe Roots Blowers play a crucial role in various stages of the treatment process. Heres how they are typically used:

1. Aeration: One of the primary uses of Twin Lobe Roots Blowers in effluent treatment is for aeration. Aeration is the process of adding air to wastewater to facilitate the growth of aerobic microorganisms, which break down organic pollutants. The blowers supply air to aeration tanks or basins where the wastewater is mixed and oxygen is dispersed. This promotes the biological degradation of organic matter, improving the overall treatment efficiency.

2. Mixing: Twin Lobe Roots Blowers are also used for mixing purposes in effluent treatment processes. In some treatment systems, especially those employing activated sludge processes, mixing is essential to ensure uniform distribution of microorganisms and nutrients throughout the wastewater. The blowers help in maintaining proper mixing conditions within tanks or reactors, facilitating effective treatment.

3. Air Sparging: In certain treatment systems, air sparging is employed to enhance the removal of volatile pollutants or to facilitate chemical reactions. Twin Lobe Roots Blowers supply air to sparging systems, where fine bubbles are released into the wastewater to promote the stripping of volatile compounds or to facilitate oxidation/reduction reactions.

4. Off-Gas Treatment: Effluent treatment processes may generate off-gases containing volatile organic compounds or odorous substances. Twin Lobe Roots Blowers can be utilized in off-gas treatment systems to convey these gases to treatment units such as activated carbon adsorbers or biological scrubbers for removal or destruction.

5. Vacuum Generation: In certain effluent treatment processes, vacuum may be required for dewatering or degassing operations. Twin Lobe Roots Blowers can be employed to generate vacuum within the system, aiding in the removal of excess water from sludge or facilitating the release of dissolved gases from the liquid phase.

Twin Lobe Roots Blower for Effluent Treatment Specifications:

1. Material: Cast Iron

2. Voltage: 220 V

3. Rated Power: 1-1.5kW

4. Suction Capacity: 30 M3/hr to 10,000 M3/hr.

5. Pressure: 1 Kg/cm2

6. Power: As per Pressure & Capacities Parameters.

7. Flow: Vertical & Horizontal

Efficient Performance for Wastewater Solutions

Our Twin Lobe Roots Blower is ideal for effluent and sewage treatment applications. The device guarantees uniform, continuous air supply, ensuring efficient wastewater aeration and treatment. Its versatile design accommodates a range of discharge capacities, from small to large-scale operations, while maintaining quiet operation below 85 dB(A). With its robust construction, this blower is engineered for reliability and long-term use.

Advanced Construction and User-Friendly Maintenance

Manufactured using cast iron, mild steel, or stainless steel, the blowers smooth surface finish boosts durability. Air cooling and oil splash lubrication keep internal components well-protected, extending service life and reducing maintenance needs. Anti-corrosive paint coating safeguards against harsh processing conditions, making it a dependable choice for demanding environments.

FAQs of Twin Lobe Roots Blower for Effluent Treatment:

Q: How is the Twin Lobe Roots Blower used in effluent and sewage treatment plants?

A: This blower is primarily used to provide continuous air supply for aeration tanks in effluent and sewage treatment plants, promoting aerobic microbial activity that is essential for effective wastewater treatment.Q: What is the operational process and technology behind the Twin Lobe Roots Blower?

A: The blower utilizes twin rotating lobes housed within a precision-finished casing to move air at a constant rate. This positive displacement action ensures reliable, pulse-free air delivery necessary for treating wastewater.Q: When should the Twin Lobe Roots Blower be maintained, and what does maintenance involve?

A: Routine maintenance, such as checking oil levels and ensuring air filters and safety valves function properly, is recommended monthly for optimal performance. Its oil splash lubrication and sturdy build mean major servicing is seldom required, thanks to its long operational life.Q: Where can this blower be installed, and what mounting options are available?

A: Intended for floor mounting, the blower can be easily installed in treatment plants or industrial facilities. Its compact design and versatile orientation options (CW/CCW rotation) facilitate integration within existing setups.Q: What are the key benefits of using this blower in treatment processes?

A: Key advantages include energy efficiency, low noise (below 85 dB(A)), long operational life with minimal maintenance, and compatibility with varying inlet/outlet sizes and installation requirements, making it adaptable to diverse wastewater treatment needs.Q: How does the blower handle different environmental conditions and processing types?

A: Designed to function between ambient and 45C, the blower features anti-corrosive paint and high-quality materials. This allows consistent operation under various environmental stresses typically found in industrial effluent and sewage treatment settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email